|

Shenzhen Enneacom photoelectricity technology Co., Ltd.

|

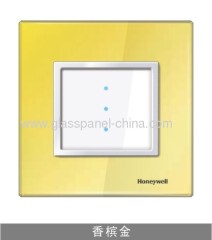

glass decorative switch plates

| Price: | 1.0~100.0 USD |

| Payment Terms: | T/T |

| Place of Origin: | Guangdong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

glass decorative switch plates, use in home and hotel.

Product edge grinding uniform, good consistency, high brightness and no drk fringe

Nearly perfect sideline processing

Product edge grinding uniform, good consistency, high brightness and no drk fringe

Disadvantages

Toughened glass must be cut to size or pressed to shape before toughening and cannot be re-worked once toughened. Polishing the edges or drilling holes in the glass is carried out before the toughening process starts. Due to the balanced stresses in the glass, damage to the glass will eventually result in the glass shattering into thumbnail sized pieces. The glass is most susceptible to breakage due to damage to the edge of the glass where the tensile stress is the greatest, but shattering can also occur in the event of a hard impact in the middle of the glass pane or if the impact is concentrated (for example, striking the glass with a point). Using toughened glass can pose a security risk in some situations due to the tendency of the glass to shatter completely upon hard impact rather than leaving shards in the windowsill.

Product Applications

Traditional mechanical switch panel

Smart Home and the weak touch switch panel terminal

Security system terminal interface

Other home appliances window protection glass window panels and electronic products

Hotel Intelligent Control System Terminal Panel

services

By the engineering to provide professional design ideas, high cost performance and good

manufacturing engineering.

To provide twice free of charge sample in design and test stages .

To establish strategic partner relationship with the customers , through the framework

agreement to schedule the capacity and open all production data.

Strict quality assurance system, excellent equipment and training-good staff is the best

guarantee of products quality and best service.

The whole link supply chain build up and internal quality system perfect implementation make

us on time delivery and obtain the custome`s good reputation.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Quartz Glass Plates

Decorative Glass

Decorative Glass Doors

Decorative Glass Bottle

Decorative Glass Jar

Decorative Glass Window

More>>